Experiment name: Application of high voltage amplifier in surface tracking corrosion analysis based on insulation resistance.

Research direction: Degree of electric trace corrosion

Experimental content: Based on the electric tracking test, the insulation properties of each ethylene-propylene rubber sample were measured after the test, and their insulation resistance was analyzed based on resistance, polarization-depolarization current and recovery voltage. First, the volume resistance, polarization-depolarization current and recovery voltage of each sample under different measurement voltages and measurement temperatures were measured in a drying oven; secondly, the effects of different fault levels on volume resistance, polarization-depolarization were analyzed in detail. The influence of chemical current and recovery voltage; finally, the insulation resistance under different measurement methods is compared to verify the reliability of the method.

Test purpose: To evaluate the tracking resistance performance of ethylene-propylene rubber according to the tracking test standards, extract tracking fault characteristic quantities, study tracking fault diagnosis methods, and evaluate the surface tracking status of ethylene-propylene rubber.

Test equipment: ethylene-propylene rubber with different degrees of tracking treatment, SLA-HV-4000 high-voltage amplifier, three-electrode system, drying box, etc.

Experiment procedure:

(1) Polarization and depolarization current of ethylene-propylene rubber;

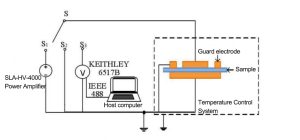

The figure below shows the measurement circuit diagram of polarization-depolarization current. During the depolarization process, the current flowing through the ethylene-propylene rubber insulation is capacitive, and the magnitude of this capacitive current is pA level. Therefore, if you want to accurately measure the depolarization current, you have high requirements for measuring equipment. In the measurement system, KEITHLEY-6517B is selected as the ammeter, and SLA-HV-4000 high-voltage amplifier is selected as the high-voltage DC power supply in the measurement. This DC source has the advantage of low noise and can ensure the reliability of measurement data. The electrode selected in the measurement is a three-electrode structure. The high-voltage end and the measurement end are used for measuring polarization-depolarization current. The host computer transmits the data collected by 6517B in real time to the host computer through the serial port for storage.

(2) Recovery voltage of ethylene-propylene rubber.

The recovery voltage method is a research based on the dielectric response theory and is a way to characterize dielectric polarization in the time domain. During the measurement process, the recovery voltage is not easily affected by external electromagnetic interference, and the measurement results are relatively stable and easy to observe.

The measuring circuit of the recovery voltage is shown in the figure. The DC voltage source selected for measurement is SLA-HV-4000 high-voltage amplifier. The voltage value selected during measurement is 400V. The voltage measurement range of the voltage measurement unit fully meets the measurement requirements. After the measurement is completed, the host computer transmits the real-time collected data to the host computer for storage through the serial port.

Test Results:

(1) The influence of trace size;

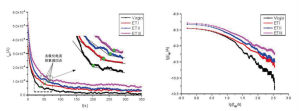

In the initial stage of discharge, as the degree of trace corrosion deepens, both the initial current and the discharge speed during depolarization gradually increase, and the more severe the degree of trace corrosion, the greater the current value at the stable moment of depolarization current attenuation. big. It can be seen from the test results that there are obvious differences in the depolarization current curves of each sample. The decay of the depolarizing current has a notch throughout the depolarization process.

Depolarizing currents at different stages of tracking development (Left)

Depolarization current at different tracking development stages in logarithmic coordinate system (Right)

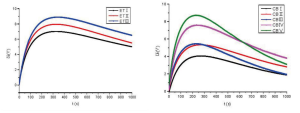

(2) As the degree of trace corrosion and insulation contamination increases, the volume resistance of ethylene-propylene rubber gradually decreases, and the polarization-depolarization current and recovery voltage gradually increase. That is, the magnitude and changes of insulation resistance, polarization-depolarization current and recovery voltage can reflect the insulation fault situation.

Recovery voltage under different tracking corrosion degrees (Left)

Recovery voltage under different toner contamination levels (Right)

The amplifier’s role in this experiment: amplifies voltage and acts as a DC current source.