Test name: Non-destructive testing of pear hardness based on acoustic response method of power amplifier.

Research direction: Nondestructive testing

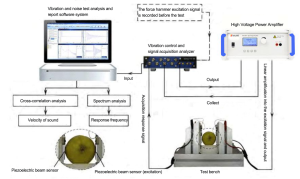

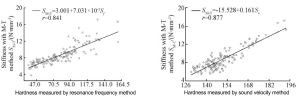

Experimental content: In this study, a detection device for signal excitation and sensing by piezoelectric beam sensor was built, the stability of signal detection was analyzed, the resonance frequency and sound velocity of pear were extracted, and the hardness of pear was evaluated. Then, linear regression analysis was performed between the evaluation hardness of these two response parameters and the measurement results of the M-T puncture method (Magness-Taylor) to construct the detection model of the hardness of fragrant pear.

Objective: To detect and distinguish the difference of internal quality of fragrant pear by non-destructive testing

Test equipment: Pear, test bench, piezoelectric beam sensor, SLA-HV-400S high-voltage power amplifier, vibration control and dynamic signal acquisition analyzer, computer, etc.

Experimental process:

(1) The construction of the test platform;

(2) Signal acquisition and processing;

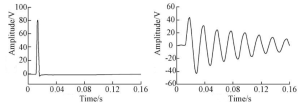

a. Excitation signal b. Response signal

According to the acoustic and vibration test, the fruit sample is usually excited by force hammer. In order to reduce signal interference and obtain strong excitation response signal, the Ve signal is linearly amplified by power amplifier.

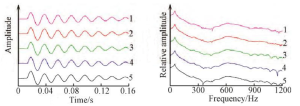

(3) Stability test of response signal;

In order to observe the stability of response signal, the same test point of pear was repeated for 5 times.

a. Time domain response signal

b. Frequency domain response signal

(4) Test the influence of different measuring points on acoustic vibration test;

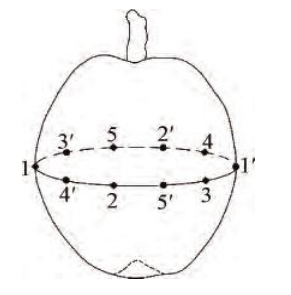

5 fragrant pears were randomly selected, as shown in the figure, and 5 measuring points were evenly arranged on the equatorial line of fragrant pears for excitation and signal sensing, so as to observe whether there were differences in response signals of fragrant pears at different excitation sensing locations.

(5) Skin puncture test was performed at 5 points randomly selected at the equator of pear by TA.XT Plus texture analyzer. Using a cylindrical probe with a diameter of 5 mm, the puncture speed was set at 1 mm/s and the puncture depth was 8mm. The hardness measured by M-T puncture method was calculated according to the slope of force-deformation curve of pear before puncture rupture, and the average value of 5 measurements was taken as the hardness of pear SM-T, N/mm.

Test results:

The resonance frequency method combined with sound velocity method can also detect the hardness of fragrant pear, and the correlation coefficient of the detection model is 0.938. The sensitivity of this model is 67.30%, which is closest to that of M-T puncture method. The accuracy of the model was higher (86.7%) when it was applied to distinguish the rough skin and normal fruit of fragrant pear, which could provide a strategy for the development of non-destructive testing technology of fragrant pear hardness by acoustic and vibration method.

The performance of the amplifier in the experiment: linear amplification signal and output, excitation of the sensing point